3D Printing Materials

When it comes to 3D printing, there are many different types of materials. Selecting the appropriate material is essential as it directly affects the functionality, quality, and durability of the 3D-printed parts.

In this article, we will discover the most popular FDM-3D printing materials that we use at “Creatables 3D”

(a 3D printing service provider in Egypt).

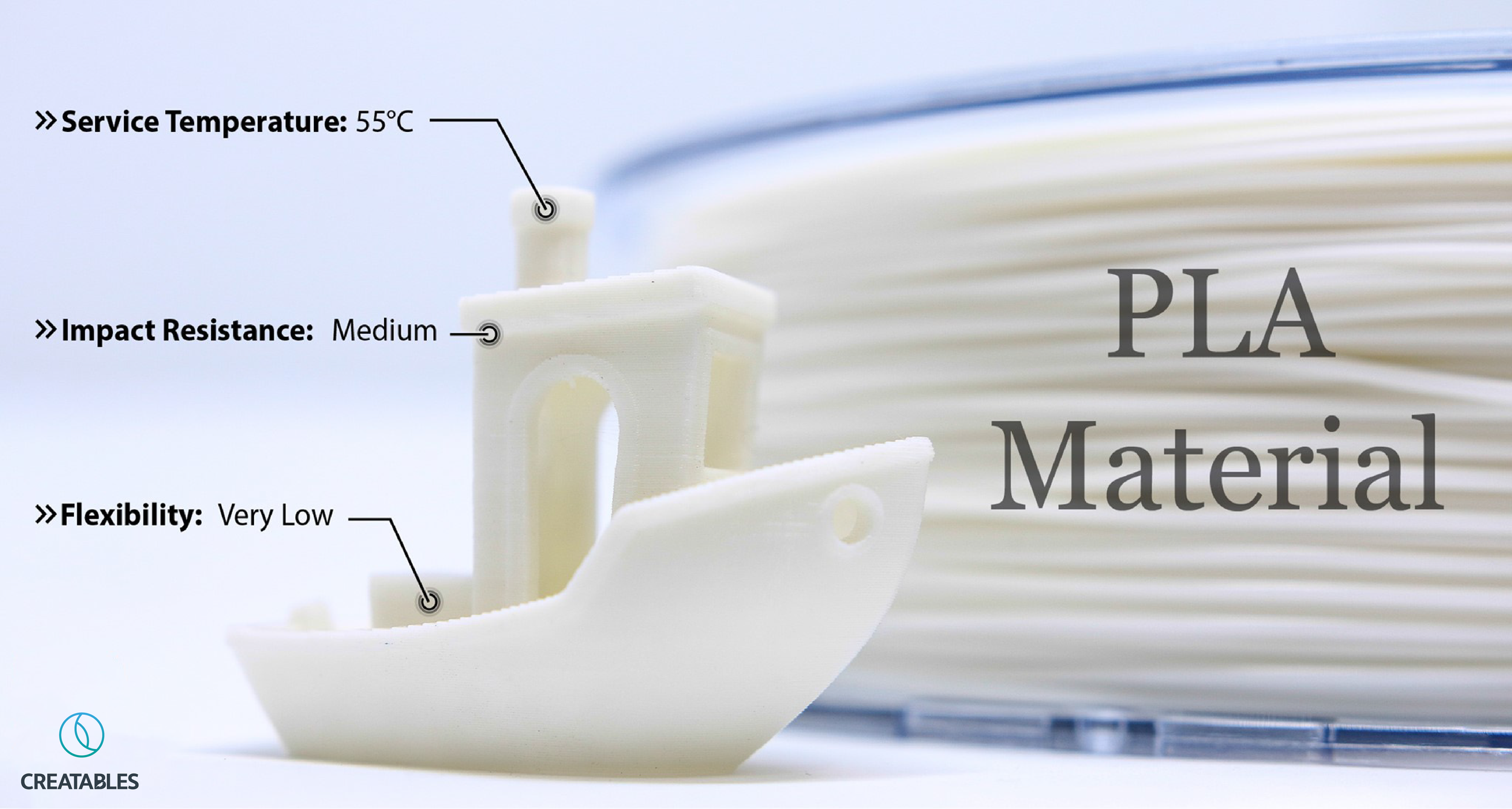

PLA

Main Characteristics:

- Low service temperature, can’t withstand temperatures higher than 55°C

- Low flexibility and impact resistance

Applications:

- Props and prototypes

- Architecture maquettes, toys, figurines, and mock-ups

(used when visual quality is important and temperature resistance is not required)

ABS

Main Characteristics:

- High service temperature, meaning it can withstand temperatures up to 95°C

- Moderate flexibility and high impact resistance

Applications:

- Mechanical parts that will undergo high stresses and impacts

(e.g. gears, electronics enclosures, etc.)

- Any parts where temperature resistance is more important than visual quality (e.g. motor brackets, functional car parts, etc.)

PETG

Main Characteristics:

- High service temperature, meaning it can withstand temperatures up to 80°C

- Moderate flexibility and high impact and fatigue resistance

- High UV resistance, meaning it can be exposed to the sun

Applications:

- Mechanical parts that will undergo repeated stresses and impacts

(e.g. fastening clips, switches, living hinges, drone parts, etc.)

- Any parts where UV resistance is required or parts that will come in contact with food

Nylon

Main Characteristics:

- High service temperature, meaning it can withstand temperatures up to 80°C

- High flexibility and very high impact and material strength

(perfect for parts requiring some flexibility and will undergo extreme stresses)

- High resistance to solvents and chemicals, making it highly durable.

Applications:

- Parts requiring excellent mechanical strength

(e.g. gears)

- Any parts where it will likely need to be contacted with some chemicals

(e.g. medical devices, lab equipment)

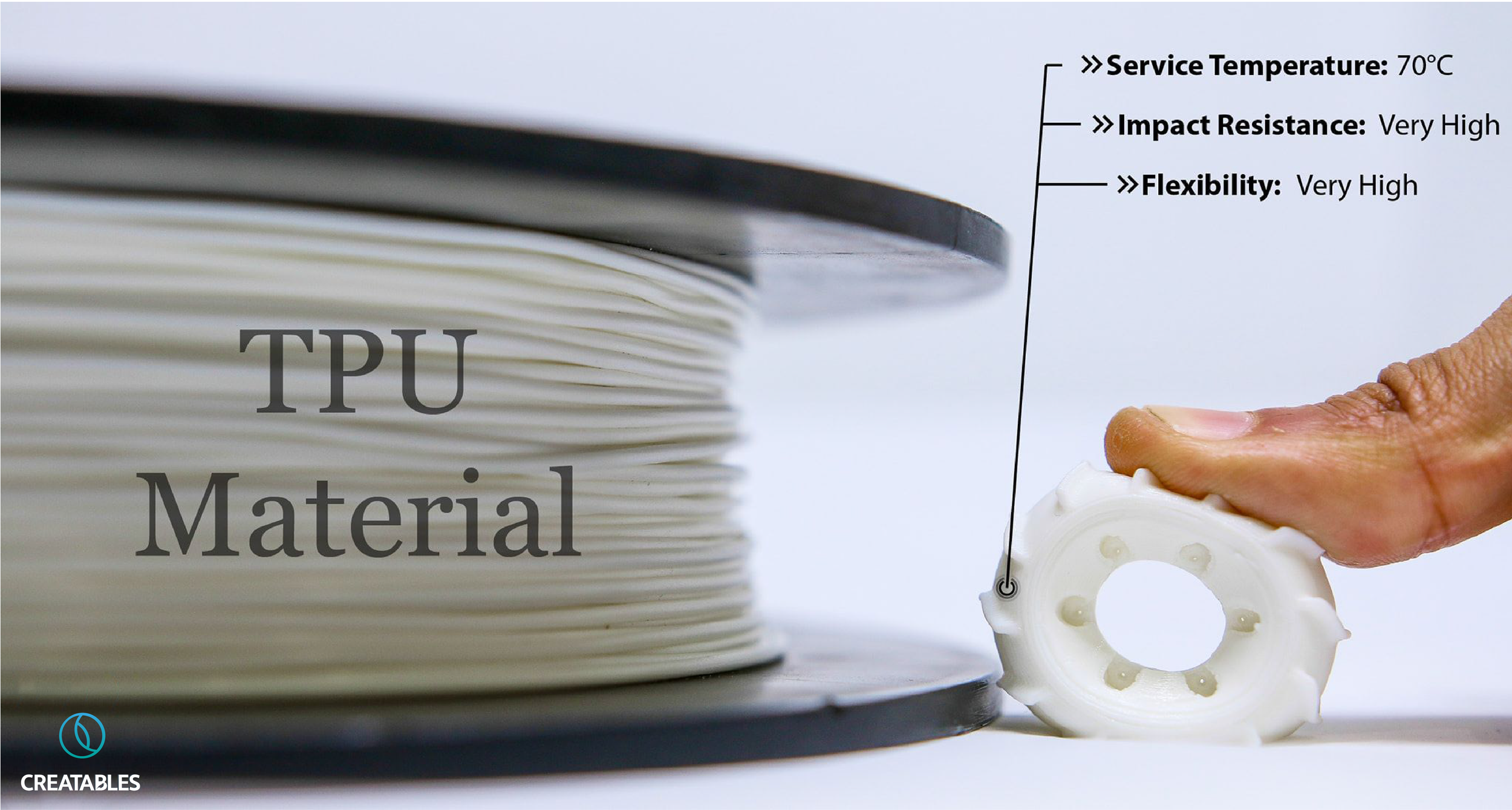

TPU

Main Characteristics:

- Average service temperature, can withstand temperatures up to 70°C

- Very high flexibility (rubber-like material) and extremely high impact resistance.

Applications:

- Parts requiring significant flexibility and rubber-like characteristics

(e.g., sealing rings, flexible covers, RC wheels)